Sustainable Gold Recovery with Activated Carbon: CIP & CIL Solutions by Bygen

Gold mining and waste recycling rely on activated carbon as a critical component for extracting gold in Carbon-in-Pulp (CIP) and Carbon-in-Leach (CIL) processes. In modern mining, activated carbon in mining operations serves to adsorb dissolved gold from cyanide leach solutions – a pivotal step that directly influences yield.

Discover how Bygen’s advanced low-temperature activated carbon (LTA) technology delivers highly efficient, sustainable gold recovery, optimising CIP/CIL extraction performance, while helping mining operations meet both production and environmental targets.

Gold Recovery with Activated Carbon: CIP and CIL in Mining

Carbon-in-Pulp (CIP) Gold Recovery Process

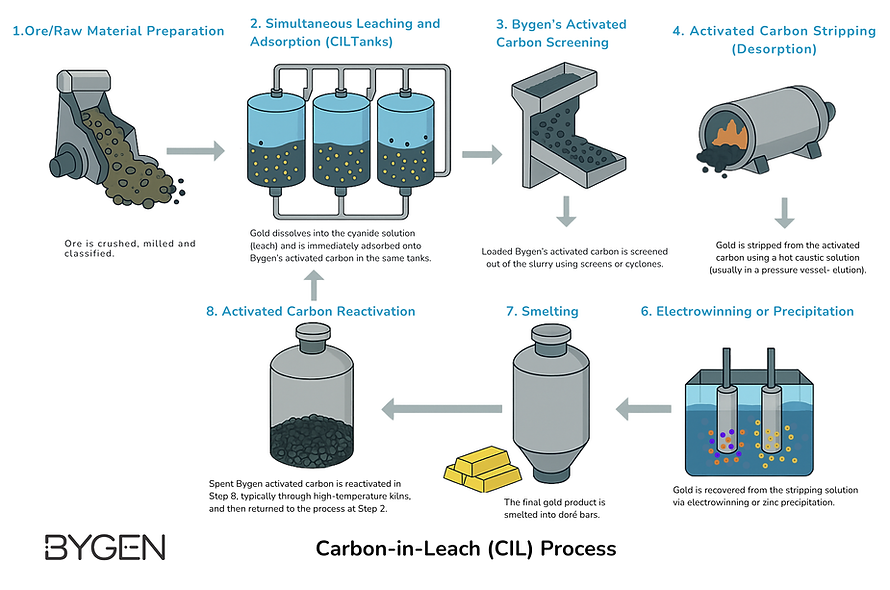

carbon-in-leach-cil-gold-recovery-process-bygen

Activated carbon is used to adsorb gold (as a gold-cyanide complex) from the leached slurry, after which the “loaded” carbon is separated for gold elution and carbon regeneration.

Activated carbon’s outstanding adsorption properties allow it to selectively capture gold from complex mixtures, making it indispensable for these processes. Essentially, any gold that remains unadsorbed by carbon would remain in solution and be lost when the solution is discarded or treated by other methods – an outcome no operation can afford. By using activated carbon in CIP/CIL, mines routinely achieve high gold recovery rates, as the carbon can be loaded with several kilograms of gold per ton of carbon before it is processed to extract the gold. The loaded carbon is then sent through an elution (desorption) process to strip off the gold, yielding a concentrated gold solution for final recovery, while the carbon is regenerated for reuse. This cyclic process is efficient and cost-effective, but it depends heavily on the quality and consistency of the activated carbon employed.

The Need for Sustainable Gold Recovery

Despite its central role in gold extraction, conventional activated carbon presents sustainability challenges. Traditional production of activated carbon often uses coal or other non-renewable feedstocks and requires energy-intensive activation (heating to high temperatures, sometimes above 800°C, with steam or harsh chemicals). This results in significant carbon emissions and a large environmental footprint for each ton of product. Moreover, many mining operations source activated carbon from overseas manufacturers, leading to long supply chains with additional emissions and potential procurement risks. For mining companies facing increasing pressure to improve their environmental, social, and governance (ESG) performance, the carbon footprint associated with gold recovery processes is an area ripe for improvement.

Sustainable gold recovery demands an alternative to standard activated carbon – one that maintains or improves performance while reducing environmental impact. In practice, this means using renewable, sustainably sourced agricultural by-products and biomass materials, cleaner production methods, and securing a local or regional supply to reduce transportation emissions. By transitioning to more sustainable activated carbon, gold producers can lower the overall environmental impact of the CIP gold extraction and CIL process for gold recovery, helping meet carbon reduction targets and demonstrating a commitment to responsible mining practices. This is where Bygen’s innovative solution comes into play.

Bygen’s Low-Temperature Activated Carbon: A Sustainable Solution for Gold Extraction

Bygen addresses these challenges by delivering a new class of low-temperature activated carbon (LTA) that is both high-performance and environmentally friendly. Bygen’s patented LTA technology produces activated carbon at substantially lower temperatures than conventional methods, using a proprietary gas blend that eliminates the need for fossil fuel-based heating during activation. This innovation dramatically reduces the energy usage and emissions associated with production, shrinking the carbon footprint of each kilogram of activated carbon.

What sets Bygen apart?

Below are key differentiators of Bygen’s sustainable activated carbon and why they matter for CIP/CIL gold recovery:

Low-Temperature Activation (LTA) Technology

Bygen’s patented process activates carbon at low temperatures using a special gas mixture. This method avoids the high-temperature furnaces or strong chemical agents typical in standard activation, drastically cutting energy consumption and greenhouse gas emissions. The result is a carbon-negative production process that contributes to your operation’s sustainability goals.

Sustainable Feedstock

All of Bygen’s activated carbon is produced from renewable, sustainably sourced biomass rather than coal or virgin wood. Feedstocks include agricultural by-products like nut shells (e.g. almond, walnut, hazelnut shells) and sustainably managed wood waste. By repurposing these agricultural by-products, Bygen creates high-quality activated carbon while supporting a circular economy and avoiding the environmental costs of mining or importing coal-based carbon.

Carbon Sequestration Benefits

Uniquely, Bygen’s production process sequesters CO₂ as part of making activated carbon. For every kilogram of activated carbon produced, approximately 2 kilograms of CO₂ are permanently captured. This means using Bygen’s product can actually reduce net CO₂ emissions in your supply chain. Mining operations striving for carbon-neutral status can benefit from this carbon-negative material, and it may even unlock carbon credits or other sustainability incentives.

Regional Supply Chain & Reliability

Bygen is establishing production facilities regionally (with headquarters in Australia and expanding internationally), providing a local supply of activated carbon for the mining industry. A shorter, regional supply chain means more reliable delivery times, reduced shipping costs, and lower transport emissions. Procurement leads can have greater confidence in supply security and inventory management, avoiding the risks associated with importing carbon from distant suppliers.

Premium Quality and Performance

Bygen’s focus on sustainability does not compromise performance. The activated carbon produced meets or exceeds industry standards for gold recovery applications. Bygen maintains strict quality assurance protocols – testing its activated carbon to relevant ASTM standards and verifying results with independent laboratories – to ensure consistent adsorption capacity, hardness, and durability required for rigorous CIP and CIL operations. In practice, mines can directly substitute Bygen’s carbon into their gold extraction circuits without process changes, expecting efficient gold loadings and reliable attrition resistance comparable to (or better than) conventional carbons.

Crucially, these advantages translate into tangible benefits for gold recovery operations. Bygen’s LTA carbon exhibits the high adsorption kinetics and gold loading capacity needed for CIP/CIL, while its low ash content and hard granule structure minimise fines and loss of carbon in the circuit. The use of sustainable, low-carbon activated carbon in mining not only helps companies meet environmental targets but also can improve stakeholder perceptions and regulatory compliance in an era where responsible sourcing is increasingly mandated.

Extending Sustainable Gold Recovery to E-Waste Recycling

The principles of carbon-in-pulp and carbon-in-leach aren’t limited to traditional mining – they are also being applied in electronic waste (e-waste) recycling to reclaim gold from discarded electronics. Circuit boards and electronic components contain trace amounts of gold, which can be leached out using hydrometallurgical methods (often involving cyanide or alternative leachants) and then recovered using activated carbon adsorption. In fact, adsorption methods in e-waste recycling typically mirror mining techniques: after leaching gold into solution, the gold cyanide complex is adsorbed onto activated carbon particles and later desorbed for final recovery. These are essentially the same CIP/CIL processes, adapted for a different feed material, and they rely on quality activated carbon just as heavily.

Using Bygen’s sustainable activated carbon in e-waste gold recovery provides a twofold environmental benefit. First, it enables the recycling of precious metals from electronic scrap, reducing the need for virgin gold mining. Second, it ensures that the recovery process itself is more sustainable, since the carbon adsorbent is produced in a carbon-negative way rather than contributing additional emissions. Environmental consultants and e-waste processors can appreciate that Bygen’s product helps close the loop: waste biomass is converted into activated carbon, which is then used to extract gold from electronic waste, ultimately diverting both agricultural and electronic waste from landfill. This synergy supports corporate sustainability initiatives and can make the overall lifecycle of gold recovery much greener. Bygen’s carbon is also robust against the chemical conditions often found in e-waste leaching (acidic or basic solutions, presence of other metals), ensuring reliable performance across various recycling processes.

Lead the Future of Gold Recovery with Bygen

As the mining and recycling industries strive for greener operations, partnering with a supplier that can deliver results without compromising on sustainability is key. Bygen’s low-temperature activated carbon empowers gold recovery processes – from major mining CIP/CIL circuits to boutique e-waste recycling setups – to become more efficient and eco-friendly. It allows you to recover gold responsibly while maintaining the high adsorption performance your process demands.

By choosing Bygen as your activated carbon provider, you’re not just buying a product, you’re gaining a sustainability advantage and a technical partner dedicated to your success. Imagine achieving your gold production targets while also cutting CO₂ emissions and supporting a regional supply chain – that’s the difference Bygen brings to the table.

Ready to enhance your gold recovery process with a premium, sustainable solution?

Contact Bygen today to discuss how our activated carbon can improve your CIP/CIL operations or e-waste gold recovery project. Our team of experts is available to provide technical consultations, assist with product trials, and tailor an activated carbon supply program that meets your needs. Together, let’s build a more sustainable future for gold recovery – one carbon filter at a time.

CONTACT US

38 Mercedes Drive

Thomastown, VIC 3074

Phone: +61 3 9465 2140

General Enquiries: info@bygen.com.au

Sales Enquiries: sales@bygen.com.au